Attention to durability of steel structures and components has important environmental, economic and social consequences. Some of these are less obvious than others.

The overall economic cost of corrosion has been studied in several countries. It is commonly estimated at up to 4% of gross domestic product.

The overall economic cost of corrosion has been studied in several countries. It is commonly estimated at up to 4% of gross domestic product.

The long-term durability provided by galvanizing is achieved at relatively low environmental burden in terms of energy and other globally relevant impacts, especially when compared to the energy value of the steel it is protecting.

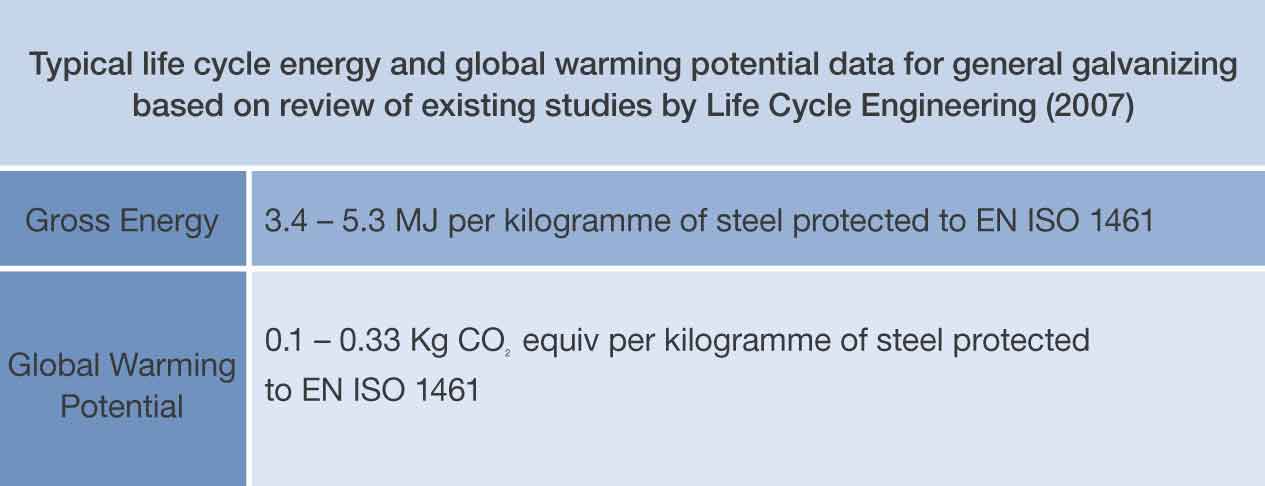

A review of available life cycle studies by Life Cycle Engineering (Torino, Italy) has indicated the typical metrics shown in the table below. The range represents variations in type of steel component, geographical factors and study methodology.

Using this knowledge of the environmental burdens of corrosion protection with galvanizing, it has been possible to compare the consequences of the different choices of corrosion protection systems. Several studies have demonstrated the high economic and environmental costs associated with the repeated maintenance painting of steel structures. These burdens can be significantly reduced by an initial investment in long-term protection.