Manufactured from the most abundant element on earth, iron, steel can be recycled or reused endlessly without detriment to its properties.

Its superior strength-to-weight ratio means a little steel goes a long way, giving specifiers complete flexibility to achieve their most ambitious designs. Manufactured in a controlled factory environment, pre-engineered steel components are delivered to site ready for rapid assembly, with no waste.

The nature of the steel construction process is the source of numerous sustainable benefits. All of the fabrication, testing and certification takes place in a safe, carefully controlled and monitored factory environment. Here, consistently high quality standards can be maintained and assured, with each component manufactured to the exact specifications of each project. This leads to quicker, safer and more predictable on-site operations. Offsite construction has clear environmental benefits, with on-site waste virtually eliminated and fewer deliveries to site, cutting carbon emissions associated with transport.

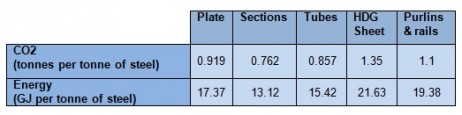

The CO2 content of structural steel

To calculate the environmental impacts of steel manufacturing, the World Steel Association adopts the ‘system expansion’ method of life cycle assessment, which is the preferred approach of the ISO 14040 series of environmental standards. This approach considers all new steel to be part of a single global system of supply and demand. Credits are given for co-products used in the manufacturing process which save energy or emissions, such as process gases being used to generate electricity. An example of the calculation method for the carbon dioxide emissions associated with steel production can be viewed at www.corusconstruction.com

To calculate the environmental impacts of steel manufacturing, the World Steel Association adopts the ‘system expansion’ method of life cycle assessment, which is the preferred approach of the ISO 14040 series of environmental standards. This approach considers all new steel to be part of a single global system of supply and demand. Credits are given for co-products used in the manufacturing process which save energy or emissions, such as process gases being used to generate electricity. An example of the calculation method for the carbon dioxide emissions associated with steel production can be viewed at www.corusconstruction.com

Benefits of using steel

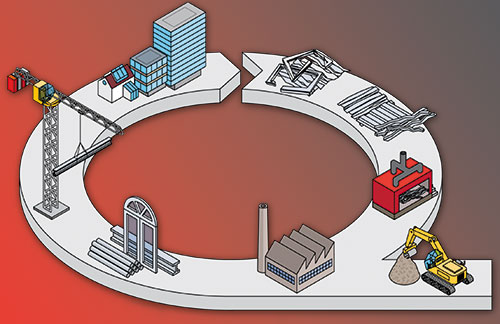

Multicycling

Steel can be reused repeatedly without ever losing its qualities as a building material. This unique characteristic gives all steel a high value at all stages of its life cycle. The recovery infrastructure for steel recycling is highly developed and highly efficient, and has been in place for decades. Current recovery rates from demolition sites in the UK are 99 % for structural steelwork and 94 % for all steel construction products – figures that far exceed those for any other construction material.

Reusable

Because steel frames are essentially a kit of parts, they can easily be dismantled and reused. Bolted connections allow components to be removed in prime condition and easily reused either individually or en masse as entire structures. It means that steel components are perpetually reused in a continuous loop, and never sent to landfill.

Fast

Fast

The speed of steel construction has made it the framing material of choice for the UK construction sector. A shorter construction programme reduces disruption and disturbance around the site. Steel is relatively clean and quiet to erect, and requires few site deliveries. Speed of construction delivers an economic benefit too, which is fundamental to sustainable development.

Safe

Industry surveys consistently demonstrate that steel is the safest construction material. Components are fabricated offsite in a safe, controlled factory environment.

Zero waste

When you specify steel for a building, you can rest assured that it is unlikely ever to become waste. Steel always has a value and is only ever sent to landfill as a last resort. Waste generation is one of the least sustainable aspects of construction. Choosing a steel-framed building is the simplest and most effective way to reduce waste. Even during steel manufacture and fabrication, any swarf or offcuts are recovered and recycled in the steel-making process.

Steel embodied carbon

Carbon and energy impacts of steel products:

It is standard practice to express these figures on a per tonne basis. This may give the impression that steel has higher impacts than other construction products. However, steel has a higher strength-to-weight ratio than most other structural materials meaning that one tonne of steel goes a lot further. As a result, the CO2 emissions associated with any steel building will be lower.

Cradle-to-gate-values

There are other values in circulation for the carbon content of steel. Some are higher and some are lower than the values in the table opposite. Most other values have been derived by less rigorous methods than system expansion. These other methods generally rely on a cradle-to-gate analysis and thus ignore the environmentally beneficial effect of recycling, which only becomes apparent during the full cradle-to-grave life cycle. Inferior cradle-to-gate methods are used for comparison because other material industries cannot provide robust cradle-to-grave data to the level of the steel industry.

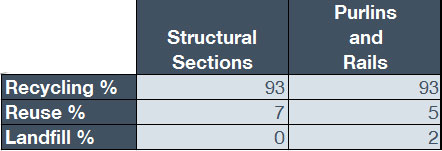

Steel recycling

Steel is the world’s most recycled construction material and approximately 40% of all steel production is based on recycled scrap. Over 500 million tonnes of steel are multicycled worldwide each year – equivalent to 180 Eiffel Towers every day.

Steel used in construction has a very high rate of recycling at end of life. For example, in the UK, 87% of constructional steel is recycled; 10% is reused and only 3% goes to landfill.

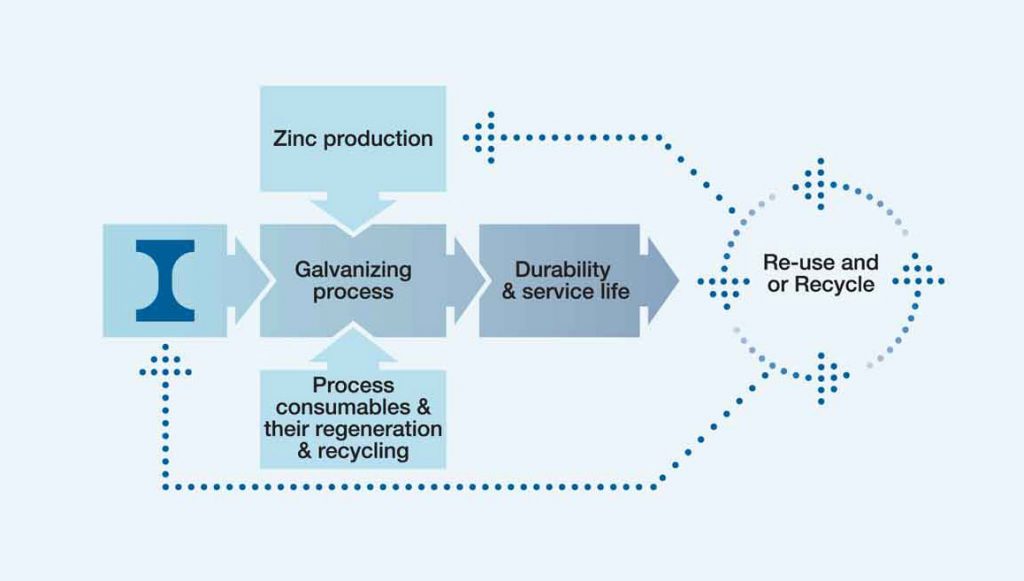

The life cycle of hot dip galvanized steel

Recycling steel as scrap

Some 86% of structural steel is recycled as scrap charge used in furnaces and 13% is dismantled and used directly for new structures. Only 1% of all steel that is made is lost to landfill or rust. By comparison to other materials – such as concrete – when steel is removed during demolition of buildings no material is left unsalvaged. That means there is no residue to contaminate the site in years to come – it has all been removed. Research indicates that when steel is used instead of concrete in construction and demolition, steel offers a 19% reduction in CO2 footprint.