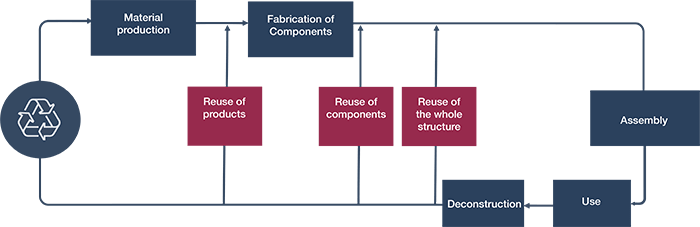

Galvanized steel is the perfect circular material to ensure that buildings and structures can be designed with maximum flexibility and to enable construction products to be used across multiple life cycles. Future designs of steel structures will become more modular and utilise bolted connections to ease deconstruction and make components more widely suitable for reuse. Galvanizing creates more value to these reused components as they do not require further protective treatment and the components themselves will be in good condition at the point of reuse.

Galvanized steel will not suffer from demounting and remounting activities, as opposed to painted steel which will need to be repainted or at least repaired. Moreover, galvanizing offers longer lifetime expectations to steel than other coating systems, which allows frequent reuse of the material.

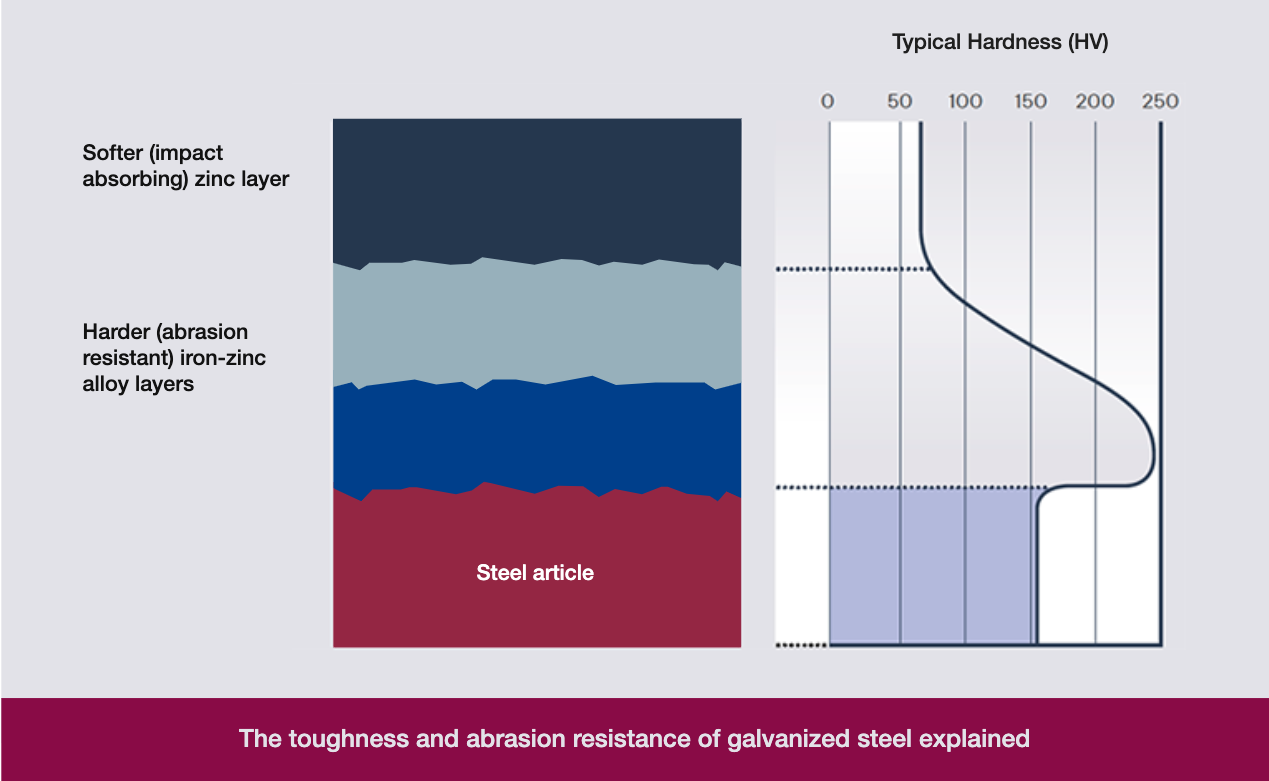

In addition to its durability, the toughness and abrasion resistance of galvanized steel, allows for multiple reuses of steel components. This has proven itself in a wide variety of applications – from scaffolding that is reused countless times to temporary bridges that are designed for rapid deployment in disaster zones but often become a vital part of the local infrastructure and may enjoy many decades before moving on to their next location.

These same principles and experience with temporary structures and reusable components are now being applied to the design of more complex structures that require flexible solutions for the circular economy.

Provisions for greater reuse of steel structures

PROGRESS (PROvisions for GREater reuse of Steel Structures) was an EU RFCS-funded project focused on the reuse of single-storey buildings. The study and its recommendations provide additional impetus to the future use of galvanized steel to maximise reuse opportunities.

The project has delivered recommendations and practical information on the fabrication and detailing of single-storey buildings made from reclaimed steel, and on the design of buildings for future demounting and reuse.

Future optimization of connections and other design details will further reinforce the partnership between galvanizing and steel construction. For example, the use of bolted connections has the dual benefit of enhancing prospects of reuse whilst also increasing the size of sections that can be dipped in a hot dip galvanizing bath.

________________

Reuse of Construction Materials – Case Studies

Gramsbergen

Location: Netherlands

Structure Type: Football Stand

An existing Elascon stand was saved from demolition thanks to the enthusiasm and decisiveness of one man. In summer 2011, Harry Haverkotte, former board member of SV Gramsbergen, heard that their neighbours from Hoogeveen would move to a new sports park. The good condition of the main grandstand caught his eye so he bought it for €7,000 which included the cost of disassembly.

Images © FC Gramsbergen/Maité Thijssen/Zink Info Benelux.

The excellent state of the galvanized steel was confirmed during disassembly. The outer structure had spent 40 years exposed to the weather, but the galvanized steel was in perfect condition and did not need to be regalvanized. The remaining galvanized coating is more than 100μm thick and the stand will last for many more decades.

________________

Dursley Treehouse

Location: Gloucester

Architects: Millar + Howard Workshop

Designed to have minimal impact on the surrounding trees and to preserve the natural habitat of the site, Dursley Treehouse has garnered much interest for its beautiful cantilevered structure, its low environmental impact and for the romanticism of living in a ‘treehouse’. Wide use of reclaimed, reused, recycled materials throughout the project saw it win many awards including our GAGA 2018 sustainability prize.

The brief for the house was to gain planning permission for a site which had twice before been refused planning for conventional houses. The 27 protected trees posed a big constraint and dictated the location of the building within the site.

Images © Charles Hosea Photography

________________

Garsington Opera Pavilion

Location: Gloucester

Architects: Robin Snell & Partners

Garsington Opera’s move to Wormsley, a lush English pastoral estate, significantly upgraded their facilities in line with the expectations of 21st Century opera goers.

The new pavilion offers superb acoustics, increased comfort and a perfect setting in which to experience opera performances of the very highest quality. The 600-seat summer pavilion is designed to be demounted annually within 3-4 weeks and will leave no permanent trace when removed.

This project was only possible using galvanized steel and fabric construction, using design innovation and testing to create the shape and form of the auditorium, providing the required acoustics for international standard opera. In these respects it is a world first.

Images © Dennis Gilbert and Mike Hoban.

________________

You may also be interested in: