Gert-Jan Vroege, Search Consultancy B.V., the Netherlands

Perspectives on Sustainability

Purchasers from public organizations increasingly use environmental impacts of products to inform their buying decisions. The EU Directive 2004/18/EC ‘Coordination of procedures for the award of public works contracts, public supply contracts and public service contracts’ allowed EU Member States to add sustainability criteria for awarding public projects.

In order to facilitate the environmental performance calculations, a selection of tools have been developed. These tools consist of three elements – (1) front-end; (2) the calculation engine and (3) the products database. The front-end and calculation engine are usually combined. The most popular in the Netherlands are Greencalc+ for buildings and DuboCalc for civil works. These calculation engines are based on the European standard for environmental product declarations – EN15804.

All these tools use the Dutch National Environmental Database as a basis for their environmental data. The database is coordinated at a national level. Building products with verified EPDs or LCAs are qualified for entry into the database. This can be done on a sector or specific product level.

Using LCA in practice: The ‘Road of the Future’

An example of the use of these criteria is the ‘Road of the Future’ process used by the Dutch municipality of Oss in Southern Holland.

The application of these criteria led the municipality to favour the purchase of galvanized steel lighting poles because of their superior environmental performance compared to other types of pole.

When considering their choice of lighting poles, the municipality asked manufacturers to provide an LCA of their poles. The choice was between galvanized steel and anodized aluminium poles that have a light point height of 9 metres. The total length is 11 metres (2 metres in the ground). Since these LCAs were not available, the municipality asked Search Consultancy to make these LCAs. The manufacturers of both types of pole fully cooperated by providing their data for the processes and materials used.

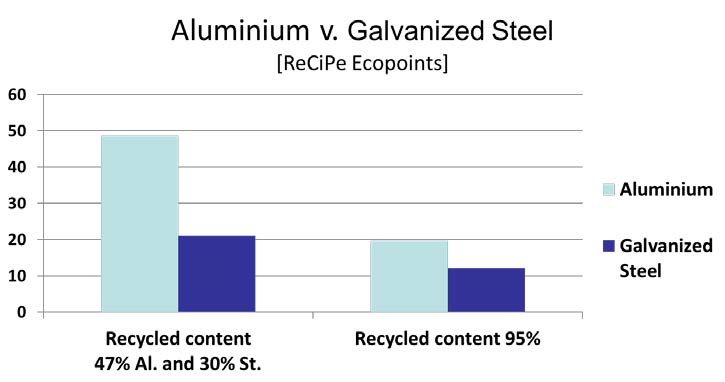

A ‘Cradle-to-Grave’ LCA was made including demolition and end-of-life scenarios and using the ReCiPe method. Two scenarios were studied. One with the sector average recycled content (30% secondary steel and 40% aluminium) and a second scenario with both materials with 95% recycled content. The results are shown in Figure 1.

Figure 1. ‘Road of the Future’. Comparison between galvanized steel and aluminium lighting poles

Summary of Paper presented at EGGA Assembly 2014, Venice, June 2014

The study showed that galvanized steel has the best environmental performances under both scenarios. The aluminium pole has a 130% worse environmental performance, but this reduces to a 60% worse performance at the higher rate of recycled content.

These LCA results were a very important basis for the municipality of Oss to choose galvanized steel lighting poles for their ‘Road of the Future’!

Comparison of existing LCAs on galvanized and aluminium lighting poles

In a further collaboration, a group of steel lighting pole manufacturers (PMF Stalen Masten; Valmont Structures and Kaal Masten) contracted the Search Consultancy to analyse all the existing LCAs for their product.

The manufacturers wanted an overview of the performance of their product compared to aluminium poles. The four LCA studies of lighting poles that were reviewed were those by:

1. Prof. Dr.-Ing. Graubner, TU Darmstad (2011)

2. Prof. Carlos A. A. Bernardo and Prof. Ferrie Van Hattum, Universidade do Minho Escola de Engenharia (2010);

3. VLCA bureau Nibe, Stichting Bouwkwaliteit (2012)

4. Msc. H.R. Spoorenberg, Search Ingenieursbureau B.V. (2012)

The basis of studies (1) to (3) are given in Table 1. The basis of study (4) is as described for the ‘Road of the Future’ described above.

Table 1. – Basis of the existing LCA studies of Lighting Poles

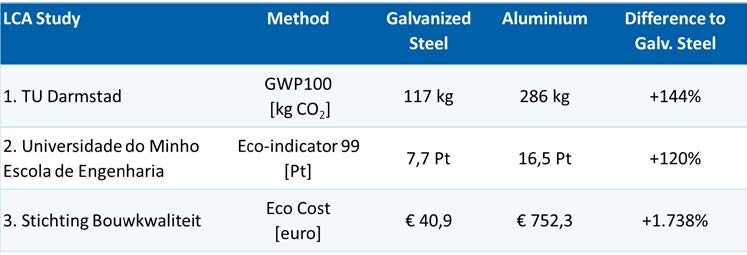

The results led to the same conclusions as for the ‘Road of the Future’. Table 2 shows the ‘Cradle-to-Gate’ results for studies (1) to (3). Galvanized steel lighting poles have the best ‘Cradle-to-Gate’ performance.

The aluminium poles have a worse environmental performance that ranges from 120% worse to 1738% worse than the steel pole. However, the Stichting Bouwkwaliteit study (Study 4) results of 1738% worse could be considered as an outlier and it is noted that this study has not been externally verified.

Table 2. – Results of three existing LCA ‘Cradle-to-Gate’ studies of Lighting Poles. (Pt = points) Summary of Paper presented at EGGA Assembly 2014, Venice, June 2014

More detailed results from the study by TU Darmstadt are given in Table 4.

Table 4 – Comparative Results for Global Warming Potential from the LCA study by TU Darmstadt

Table 3 shows the ‘Cradle-to-Grave’ results. In all, except one, of these studies galvanized steel poles also show better performance than aluminium poles.

Although the study by Universidade do Minho Escola de Engenharia shows a better performance for the aluminium pole, this is solely due to the theoretical assumption that the percentage of recycled content of aluminium is 100%.

This assumption is rarely realised in practice and the other studies reflect a more realistic scenario.

Table 3. – Results of four existing LCA ‘Cradle-to-Grave’ studies of Lighting Poles

(Pt = points; Note that Eco-indicator 99 points should not be directly compared to ReCiPe points)

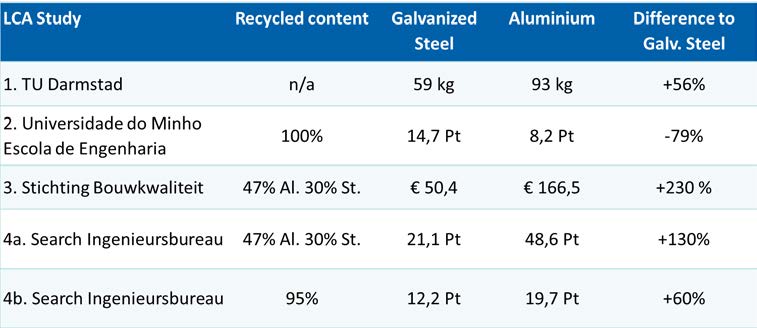

Study 4 (Stichting Bouwkwaliteit) used the DuboCalc method to calculate the MKI (Milieu Kosten Indicator) that expresses impacts in economic costs associated with aggregated environmental impacts. The study also included comparisons with carbon composite polymer lighting poles for 15 metre poles.

The composite poles showed even higher environmental costs than the aluminium and steel poles. The results of that aspect of study are shown in Figure 2.

Summary of Paper presented at EGGA Assembly 2014, Venice, June 2014

Figure 2 – Comparison of MKI costs for 15m steel, aluminium and polymer composite lighting poles

Figure 2 – Comparison of MKI costs for 15m steel, aluminium and polymer composite lighting poles (Study 4 – Stichting Bouwkwaliteit).

Future developments – the Circular Economy

The circular economy is gaining in popularity in many sectors across Europe. The McKinsey report ‘Toward the Circular Economy 2012’, commissioned by the Ellen MacArthur Foundation, makes this trend clear.

It argues that a subset of the EU manufacturing sector could realise net materials cost savings worth up to $ 630 billion p.a. towards 2025—stimulating economic activity in the areas of product development, remanufacturing and refurbishment.

The use of LCA and Cradle to Cradle© approaches will continue to support the move towards that circular economy.

Further information on the analysis of comparative LCAs compiled by the steel lighting pole industry can be found at www.sustainablesteel.eu .

References

Graubner, C. (2011) Ein ökologischer Vergleich von Mastsystemen aus Schleuderbeton, Stahl, Aluminium end GFK.

Simões, C. (2010) Study of the different parameters that affect the Life Cycle

Assessment of a composite lighting column ‐ comparison with steel and aluminium

Nibe B.V. (2012), Duurzaam GWW instrument DuboCalc

Spoorenberg H.,(2012) LCA vergelijking lichtmasten N329, Oss

McKinsey (2012) Toward the Circular Economy