The New Circular Way Forward

The challenge of sustainable construction in the face of climate change has acquired a new urgency in the past few years. In response, construction professionals are adopting new practices that prioritise extended use, multiple lifecycles and modular design. It is a new, regenerative approach to the built environment which aligns with the circular economy and answers the problems of increased demand and population growth against the backdrop of finite resources.

A Voice for Sustainable Construction

The UK and Irish galvanizing industry has been part of the sustainability dialogue for a number of decades. Our new document published in collaboration with EGGA, the European General Galvanizing Association, outlines how galvanized steel is an ideal circular material and the contribution it can make helping to navigate net zero. The publication, Galvanized Steel and Sustainable Construction: Solutions for a Circular Economy offers construction professionals a clear roadmap for how to use galvanized steel to design and build structures, which offer lifetime solutions, can be disassembled, reused, re-made and lastly, recycled. It showcases outstanding projects from across Europe that highlight the best in circular design.

Understanding the Hierarchy

Galvanized steel aligns with key principles central to circular design and construction. These are:

![]() Priority One: Make (Refuse) – Design for Durability Galvanized steel offers the highest levels of durability, delivering once-only solutions that can last the lifetime of a building. This allows for an emphasis on avoiding the environmental impact of unnecessary construction.

Priority One: Make (Refuse) – Design for Durability Galvanized steel offers the highest levels of durability, delivering once-only solutions that can last the lifetime of a building. This allows for an emphasis on avoiding the environmental impact of unnecessary construction.

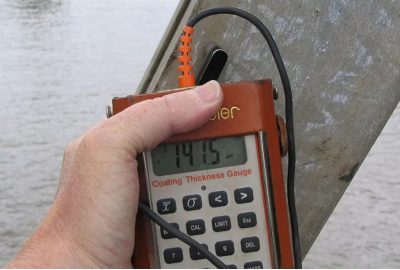

![]() Priority Two: Use (Reduce) – Carbon by Avoiding Maintenance Data on the corrosion protection offered by a galvanized coating shows how the process of galvanizing steel components reduces maintenance burdens over the lifetime of a project.

Priority Two: Use (Reduce) – Carbon by Avoiding Maintenance Data on the corrosion protection offered by a galvanized coating shows how the process of galvanizing steel components reduces maintenance burdens over the lifetime of a project.

![]() Priority Three: Reuse Galvanized steel is an ideal material for reuse, as it is robust and does not damage easily. It is suited to modular design, can be designed to be easily disassembled for reuse and can provide multiple life cycles of a building or structure. If a building is designed with reuse in mind, entire structures can be repurposed or individual components can be put to diverse use.

Priority Three: Reuse Galvanized steel is an ideal material for reuse, as it is robust and does not damage easily. It is suited to modular design, can be designed to be easily disassembled for reuse and can provide multiple life cycles of a building or structure. If a building is designed with reuse in mind, entire structures can be repurposed or individual components can be put to diverse use.

![]() Priority Four: Remake When the limits of reuse of an existing component or structure have been exhausted, galvanized steel presents an excellent choice for remaking. Galvanized steel components can be easily adapted or regalvanized and put back into service – avoiding the environmental burden of new steel production.

Priority Four: Remake When the limits of reuse of an existing component or structure have been exhausted, galvanized steel presents an excellent choice for remaking. Galvanized steel components can be easily adapted or regalvanized and put back into service – avoiding the environmental burden of new steel production.

![]() Priority Five: Recycle Steel and zinc are recycled together – without loss of properties – if the long life of galvanized steel eventually ends.

Priority Five: Recycle Steel and zinc are recycled together – without loss of properties – if the long life of galvanized steel eventually ends.

Overall recognition that the concept of a circular economy is fundamental to optimising the sustainability of materials has again brought the simplicity, flexibility and inherent recyclability of metal structures and components to the forefront of sustainable design. Hot dip galvanized steel sits perfectly within this revised thinking.

For more information, visit Galvanized Steel in the Circular Economy

The guide is available by request. Get a downloadable or printed copy here

Join the conversation

Make a comment