The challenge of sustainable construction

The creation of buildings and their lifetime use is estimated to contribute up to 40 percent of worldwide carbon emissions, issuing the construction sector a huge challenge in reducing its carbon burden and mitigating its impacts. With a growing world population and an increased use of engineered materials, the extraction of natural resources at its present rate is considered unsustainable. It is clear that a new approach, which balances rising demand with lower carbon uptake, is urgently needed.

Fortunately, ambitious objectives both at home, and internationally, support ideas to transition industry to a more sustainable model. The model keeps products and materials in use, eliminates waste and regenerates natural systems – all principles of a circular economy. By appreciating the value of raw materials and keeping buildings, infrastructure, resources and materials in use for as long as possible, the construction sector will play its role in securing a low carbon future, whilst balancing the problem of finite resources with growing demand.

The circular economy – a new way forward for Construction

A circular economy model can be used as a different way of designing and building than a traditional, linear way of construction. In place of conventional manufacture, design and fabrication, which discards materials, and which is designed from a cost driven perspective, a circular economy prioritises the idea of intelligent, reusable design.

A circular economy builds long term resilience and provides environmental and societal benefits.

According to the principles of a circular economy, products are no longer manufactured from raw materials and then discarded at the end of their useful lives, but rather a new form of intelligent design leads to products or their parts being repaired, reused, returned and recycled. In this way a circular economy drives optimal resource efficiency so as to maximize the economic well-being of everyone.

In addition, products need to be designed to be durable, easy to repair and, ultimately, to be recycled. Whilst the cost of reusing, repairing or remanufacturing products has to be competitive to encourage these practices, simply replacing a product with a new one should no longer be the norm in a circular economy. A circular economy builds long term resilience and provides environmental and societal benefits.

Recognition that the concept of a circular economy is fundamental to optimising sustainability of materials has again brought the simplicity, robustness, durability and inherent recyclability of metal structures and components to the forefront of sustainable design.

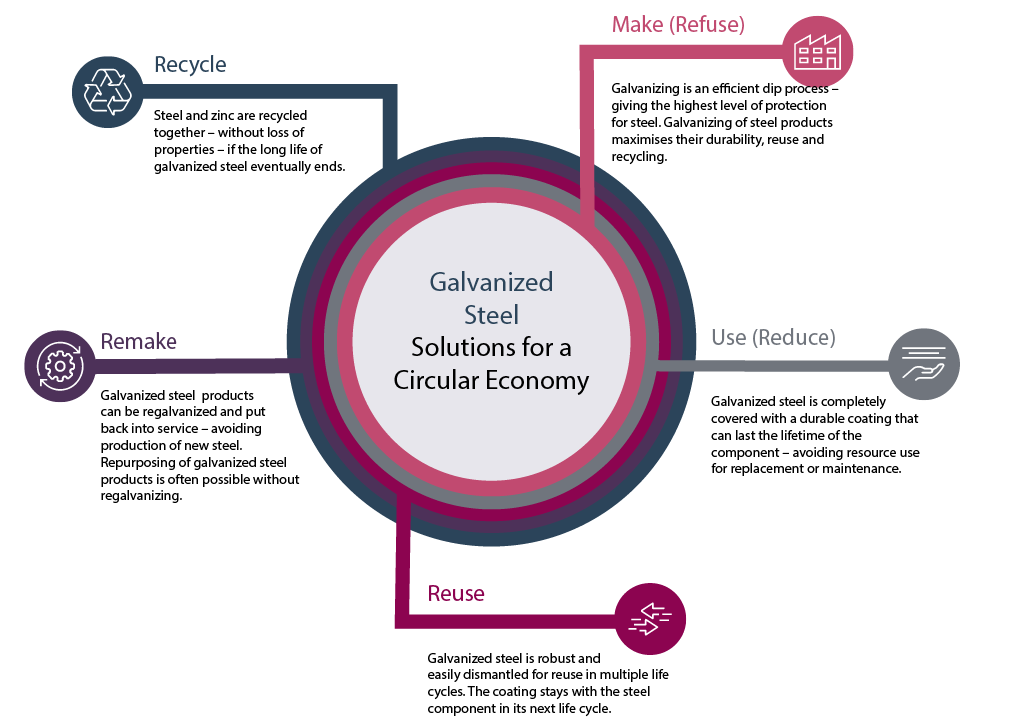

Galvanized steel: a circular material

Galvanized steel structures and components are ideal circular materials. The galvanizing industry in the UK and Ireland welcomes the increasing focus on the creation of a circular economy and embraces flexible design for durability, deconstruction, and disassembly. Galvanized steel readily facilitates the reuse, remanufacturing or recovery of materials.

If a material system was specially designed for the circular economy, hot dip galvanizing would be a perfect example:

- Hot Dip Galvanizing of steel products after fabrication delivers the highest levels of corrosion protection – the steel structure will often achieve its design life with no maintenance.

- The galvanized coating can follow the steel structure through multiple cycles of reuse.

- Galvanized coatings are bonded to the steel – allowing the steel product to be reused along with the original coating without need for recoating.

- Galvanized steel components that have reached the end of their design life, or are uninstalled for any other reason, can be regalvanized and returned to the original use.

- If the re-use cycles come to an end, both steel and zinc are recycled together in the well-established steel recycling processes with the zinc being returned, without loss of properties, to zinc production plants and eventually back into the galvanizing process.

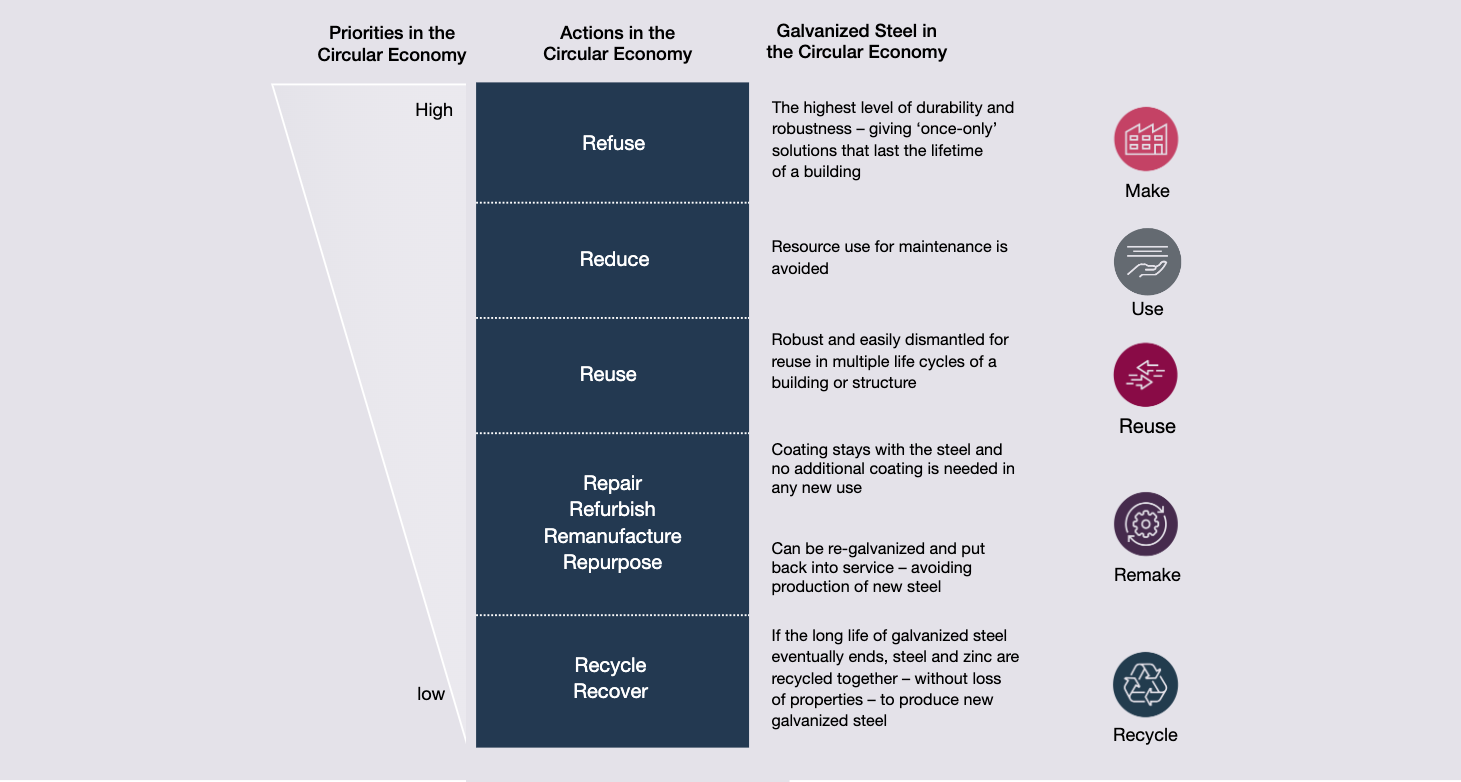

Circular Economy Hierarchical Models

At every stage of the product or building lifecycle, galvanized steel can make a contribution suited to the most efficient use of resources and the elimination of maintenance and waste.

From initial construction that offers once-only solutions which last the lifetime of a building, and steps towards stronger lighter components that use resources efficiently, to a variety of reusing and remaking options, galvanized steel offers highly flexible solutions.

The hierarchy models of a circular economy illustrate the important contribution that galvanized steel can make within a circular economy. It prioritises the once-only solutions offered by galvanized steel and the lifetime benefits of selecting such a robust and proven material.

Hierarchical models of the circular economy illustrate the importance of galvanized steel.

You may also be interested in: